January 25, 2016

INTRODUCTION

Over the past 35 years, Shenzhen has transformed from an extremely poor

fishing village to one of the most economically developed cities in

China, witnessing countless advances along the way. In May of 1980, the

city was designated one of China’s first special economic zones, acting

as a cradle for many start-ups. Today, it is China’s biggest jewelry

manufacturing and trading hub.

Over the years, Shenzhen has been at the forefront of pioneering trade reform. The “China Jewelry Index” (CJI) was initiated, born, and maintained in Shenzhen. It was launched in October, 2014, after three years of preparation. The Index, like Rapaport’s diamond report, was the first national-level database to provide comprehensive information on China’s gem and jewelry industry. Considered a milestone of business development, CJI is fully supported by the local Shenzhen government, with intellectual support from the Gem and Jewelry Trade Association of China.

Over the years, Shenzhen has been at the forefront of pioneering trade reform. The “China Jewelry Index” (CJI) was initiated, born, and maintained in Shenzhen. It was launched in October, 2014, after three years of preparation. The Index, like Rapaport’s diamond report, was the first national-level database to provide comprehensive information on China’s gem and jewelry industry. Considered a milestone of business development, CJI is fully supported by the local Shenzhen government, with intellectual support from the Gem and Jewelry Trade Association of China.

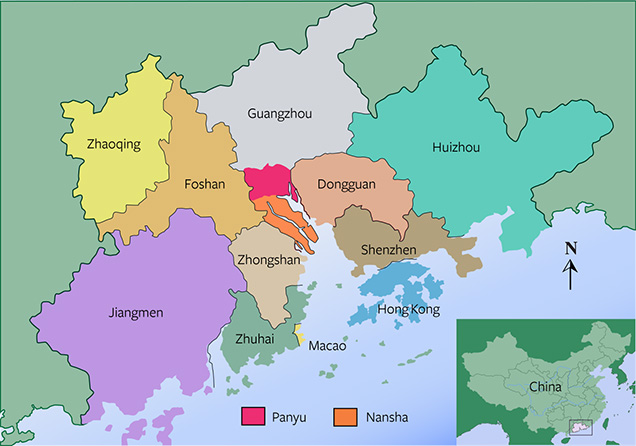

Shenzhen is located at the southern tip of the Pearl River Delta, bordering Hong Kong.

Fast economic growth boosts Shenzhen’s gem and jewelry industry. Its well-established

trading centers include large-scale operations such as the Kingliving International Jewelry

Exchange Center. Courtesy China Gems Magazine.

trading centers include large-scale operations such as the Kingliving International Jewelry

Exchange Center. Courtesy China Gems Magazine.

The city’s GDP rose from 1.96 million Chinese renminbi (RMB) in 1979 to

1,600.20 billion RMB (US $267 billion) in 2013. The growth rate in

Gross Domestic Product was 8.8 percent from 2013 to 2014, which was

higher than the overall growth rate for all of China. This fast growth

attracted new migrants from all over the country and the world. The

permanent population grew from 30,000 in the early 1980s to about 18

million today. Its demographic consists of 99 percent migrants, although

the exact population has never been consistent or easy to count.

As the industry has developed, many gem and jewelry testing labs have opened offices in

Shenzhen. This building is the National Gem and Jewelry Testing Center in Shuibei,

Shenzhen. Courtesy China Gems Magazine.

Shenzhen. This building is the National Gem and Jewelry Testing Center in Shuibei,

Shenzhen. Courtesy China Gems Magazine.

Besides being home to numerous high-tech companies, the Shenzhen Stock

Exchange, and the world’s third-busiest container port, Shenzhen is also

at the forefront of China’s gem and jewelry industry. There are more

than 3,600 registered jewelry companies, more than 5,000 licensed

individual dealers, and 29 gem and jewelry exchange centers in Shenzhen.

The industry employs more than 150,000 people. The value of total

wholesale jewelry production and the total domestic jewelry retail sales

in Shenzhen reached 100 billion RMB (about US $16.7 billion) and 140

billion RMB (about $23.3 billion) respectively in 2014.

In 2013, a group from GIA visited China to research the Chinese industry and market. During that visit, the team observed many of Shenzhen’s leading companies.

In 2013, a group from GIA visited China to research the Chinese industry and market. During that visit, the team observed many of Shenzhen’s leading companies.

HISTORY OF SHENZHEN’S GEM AND JEWELRY INDUSTRY

The beginning of Shenzhen’s gem and jewelry industry dates back to the

early 1980s, when Hong Kong jewelry manufacturers started moving their

factories and plants to mainland China. In addition to its ideal

location as a neighbor of Hong Kong, Shenzhen’s development was also

facilitated when the government started a trial of new gold-trading

policy in the city. Before that, between 1949 and 1982, it was required

that all gold production be submitted to the central bank, which then

distributed the gold to factories. Also, individual consumers were not

allowed to purchase gold. The first stage in the opening up of the gold

trade was to allow individuals to purchase gold jewelry in state-owned

shopping malls.

Since China opened its gold market to

individuals, gold jewelry has been a best seller among all jewelry

categories. Photo by Andrew Lucas/GIA, courtesy Batar Jewelry.

In the 1980s, Shenzhen’s gem and jewelry industry was very small-scale.

The main business model was called “three-plus-one,” a custom

manufacturing arrangement that used supplied materials, designs, and

samples, and—for compensation (the “plus”)—manufactured the desired

product. Many industries adopted this model at the beginning of the

reform process.

The gem and jewelry industry in Shenzhen began

with jewelry manufacturing, which is still one of the city’s pillar

industries. Courtesy Shenzhen Yuehao Jewelry.

The industry experienced its fastest growth between the end of the

1980s and the early 2000s. During that time, gem and jewelry trading

policy became more and more flexible and private businesses grew

rapidly. Consumers had more and more disposable income to spend on

luxury products like jewelry. Shenzhen Gold and Jewelry Association

formed in 1990, with support from the local government, to serve as a

bridge between government and business owners.

More and more Chinese consumers are spending

their disposable income on luxury goods such as jewelry. The fast growth

of the Shenzhen gem and jewelry industry is aided by an increase in

discretionary income. Photo by Andrew Lucas/GIA, courtesy Enzo.

After 2003, the government further reformed its taxation policies in

order to support the developing gem and jewelry industry. The formation

of gold and diamond exchanges stimulated the fast growth of the industry

in multiple areas all over the country. In Shenzhen, larger jewelry

companies quickly expanded, and brand building took over as the core

mission. In addition to being a manufacturing and trade center, Shenzhen

is also home to most major Chinese jewelry brands.

In 2005, several jewelry brands originating in Shenzhen were named “China Famous Brand.” This labeling helped them with brand promotion and sales, and caused many industry participants to realize the importance of brand building. Today, the leading brand in every sector of the gem and jewelry industry has operations in Shenzhen.

In 2005, several jewelry brands originating in Shenzhen were named “China Famous Brand.” This labeling helped them with brand promotion and sales, and caused many industry participants to realize the importance of brand building. Today, the leading brand in every sector of the gem and jewelry industry has operations in Shenzhen.

Branding became important to Chinese jewelry companies in the mid-2000s. Jewelry by

Enzo, a leading colored stone jewelry brand, is modeled by Chinese movie star Sun Ning.

Courtesy China Gems Magazine.

Enzo, a leading colored stone jewelry brand, is modeled by Chinese movie star Sun Ning.

Courtesy China Gems Magazine.

SHUIBEI: A CENTER OF SHENZHEN’S GEM AND JEWELRY INDUSTRY

Shuibei Jewelry Park covers an area of less than one square kilometer,

but it is the center of Shenzhen’s gem and jewelry industry,

encompassing more than 2,000 jewelry companies. Many companies

originated there as small studios and became leading industry brands.

Most of the area’s gem and jewelry exchange centers are clustered there

as well. Gem-testing labs and industry services such as packaging,

transport, and storage also have offices in the area.

Shuibei is the center of Shenzhen’s gem and

jewelry industry. There are over 2,000 jewelry businesses clustered

there. Courtesy China Gems Magazine.

The GIA team visited two large exchange centers and the largest

high-end jewelry club, managed by Shenzhen Creation Group. The Creation

Group is one of the leading colored stone companies in Shenzhen. It

formed in 2000 and operates a group of companies engaged in high-end and

commercial jewelry design and manufacturing, and in gemstone and

jewelry trading.

There are more than 100 jewelry shops in the

Shuibei International Jewelry Trade Center. It has four main sectors,

including a jadeite jade section. Photo by Eric Welch/GIA, courtesy The

Creation Group.

The Shuibei International Jewelry Trade Center opened in May, 2004. It

was the first centralized jewelry trading platform in Shuibei. Before

that, people who wanted to buy wholesale gemstones and jewelry needed to

go from one shop to another. This center provided the first one-stop

service for large and small wholesalers and retailers.

Karat-gold jewelry is very popular in the China

market. This display promotes the Yuehao jewelry brand, which has a

store in the Shuibei International Jewelry Trade Center. Photo by Eric

Welch/GIA, courtesy of The Creation Group.

The Shuibei International Jewelry Trade Center currently hosts more

than 100 notable local and international jewelry shops. There are four

main sectors: brands, jadeite jade, and karat gold and silver jewelry.

The company evaluates all dealers at the end of each year. Contract

renewals are based on many evaluation factors, including consumer

satisfaction. Only qualified dealers can operate their shops or booths

in the center.

The company also invests in displays designed to educate consumers and reassure them about the center’s reliability. This is especially important today since more and more trading platforms are being built and to be sustainable, owners have to make their facilities stand out.

The company also invests in displays designed to educate consumers and reassure them about the center’s reliability. This is especially important today since more and more trading platforms are being built and to be sustainable, owners have to make their facilities stand out.

Shops in the exchange centers usually carry gold,

jade, colored stone, and diamond jewelry. Wholesalers and retailers can

easily find what they want. Photo by Eric Welch/GIA, courtesy The

Creation Group.

The Royalland Jewelry Club was formed in 2009 to cater to the emerging

high-end jewelry market. It is the largest high-end jewelry club in

mainland China, with a showroom that’s more than 21,500 square feet in

size. The showroom is located on the top floor of a building and has its

own private access. The club regularly hosts jewelry salons for its

clients and is also available for private events. Independent designers

contract with the club to develop custom designs for luxury consumers.

Royalland Jewelry Club Gallery

BATAR: CHINA’S LARGEST GOLD JEWELRY MANUFACTURER

Gold jewelry has a long tradition as a best-seller in China. Batar

provides manufacturing services for almost all major gold jewelry brands

and produces one out of five gold jewelry pieces in China. The company

was registered in Hong Kong in 2001 and is now a member of the Shanghai

Gold Exchange.

In addition to gold jewelry manufacturing, Batar also deals in other gold products and in gold inheritance and investment. Batar has more than 20 subsidiaries, and sold nearly 200 tons of gold products in 2014. The company is now the main supplier of 24K gold jewelry for more than 30,000 retailers and more than 400 brand names.

In addition to gold jewelry manufacturing, Batar also deals in other gold products and in gold inheritance and investment. Batar has more than 20 subsidiaries, and sold nearly 200 tons of gold products in 2014. The company is now the main supplier of 24K gold jewelry for more than 30,000 retailers and more than 400 brand names.

Twenty-four karat gold jewelry is still the most

popular wedding jewelry in China. This suite has a traditional dragon

and phoenix theme. Photo by Andrew Lucas/GIA, courtesy Batar Jewelry.

Twenty-four karat gold jewelry is favored by Chinese consumers, who

feel that the purer the better when it comes to gold. This is unlike

other world markets in the world. Asian consumers, including those in

the Middle East, are generally gold lovers, but the highest gold purity

commonly found in those markets is 22K (91.6 percent gold).

The Batar store is always packed with gold

jewelry shoppers. The Chinese people have a never-ending passion for

high-purity gold jewelry. Photo by Andrew Lucas/GIA, courtesy Batar

Jewelry.

It is Chinese tradition to purchase gold jewelry as gifts for important

life events. At the beginning of each lunar year, consumers buy all

kinds of gold bars or decorations with designs featuring that year’s

zodiac animal. Every holiday, stores that carry gold jewelry are packed

with wealthy families and entrepreneurs who buy large gold decorative

items to show off their success. Also, increasing numbers of individual

consumers invest their increasing discretionary income in gold and

gemstones. Batar took advantage of this opportunity by collaborating

with banks to facilitate their gold investment programs.

Batar is the main supplier for gold jewelry

retailers from all over the country. Each transaction usually involves

large amounts of gold jewelry, which explains the need for these baskets

to hold the selected goods. Photo by Andrew Lucas/GIA, courtesy Batar

Jewelry.

When GIA visited a Batar store in Shenzhen on a regular business day,

the store was crowded with clients. Based on the quantity of goods they

were purchasing, it was easy to tell that most of them were wholesalers

and retailers. Large quantities of gold jewelry were collected in

baskets during the transactions, and the salespeople and buyers were

busy counting and selecting items.

Batar employs the top wax carvers in the

industry, and they pay a lot of attention to detail. This carver is

working on the original wax model for a gold ornamental object. Photo by

Andrew Lucas/GIA, courtesy Batar Jewelry.

Batar started as a manufacturer for jewelry brands outside of China.

When the domestic Chinese gold market opened up, the company became the

main manufacturer for domestic jewelry brands as well. Later, Batar

developed its own brands, including Batar Jewelry and Show King. The

company has contracts with well-known jewelry designers and never stops

inventing new techniques and designs.

Batar is a major manufacturer of gold jewelry and ornamental objects. Photo by Andrew Lucas/GIA, courtesy Batar Jewelry.

To satisfy the demand for high-purity gold jewelry, the company

invested in developing new gold jewelry manufacturing techniques in

collaboration with China Science Academy. As all goldsmiths know,

soldering is one of most important steps in making gold jewelry, but the

standard solder used in China contains only 91.6 percent gold, giving

it a lower melting temperature than pure gold. In order to significantly

improve the purity of gold items, they must use 24K material throughout

the process and also try to avoid as many soldering steps as possible.

This is the key technique that Batar uses to stay competitive.

To cater to young consumers, Batar developed techniques to make gold

jewelry reflect different colors of light. While the result is popular

with young consumers, the older generation still prefers the traditional

designs and pays more attention to the value of the material than to

its unique appearance.

A recent market survey indicated that of all 24K jewelry, chains—necklaces and bracelets—are the best sellers. Sales of gold chains account for 40 percent of the market, with rings at 17 percent and pendants at 11 percent.

A recent market survey indicated that of all 24K jewelry, chains—necklaces and bracelets—are the best sellers. Sales of gold chains account for 40 percent of the market, with rings at 17 percent and pendants at 11 percent.

Batar manufactures massive quantities of 24K gold jewelry and ornamental objects.

XINGGUANGDA: ONE OF CHINA’S LARGEST GEM SETTERS

The recipient of the 2014 JNA Manufacturer of the Year award for

gem-set jewelry, Shenzhen’s Xingguangda Jewelry Industrial Co. Ltd., is

one of the leading jewelry manufacturers in mainland China. The company

was formed in 1997 and specializes in gemstone jewelry in 18-karat gold

and platinum. In addition, Xingguangda also engages in jewelry design,

manufacturing technique research, and jewelry wholesale and retail.

Xingguangda is one of China’s leading jewelry

manufacturers. Its gem-setting techniques are very well known throughout

the industry. This worker is making the final adjustments on a high-end

diamond jewelry suite. Courtesy Xingguangda Jewelry.

After more than 20 years of operation, Xingguangda now owns four

well-known jewelry brands, more than 50 patents, and more than 3,000

retail outlets countrywide. Working closely with the China Gem and

Jewelry Industry Association, the company has been involved in the

formalization of multiple industry standards. Xingguangda had its

origins in Shenzhen, and has built a very solid base in this world-class

industry hub. The company’s core team includes its management staff and

more than 1,000 professional technicians.

Manufacturing in Shenzhen is almost always done on a large scale and

this is no different at Xingguanda, where large quantities of diamonds

are set into the jewelry they produce.

While continually increasing its manufacturing efficiency and product

quality, the company also invests in developing its jewelry design team.

Through the years, Xingguangda has won numerous awards in the National

Jewelry Design and Manufacture competition. In the most recent 2014-2015

competition, several jewelry-making technicians from the company won

individual awards.

Award-winning Jewelry Gallery

Besides its dealings in colored stone jewelry, Xingguangda also

collaborates with diamond-cutting factories to research new creative

cuts. In 2014, they launched a new diamond cut called “ten heart and ten

arrows.” This new cut has 71 facets—more than a regular round

brilliant, which has 58. The manufacturer reports that this cut’s fire

is generally 20 percent stronger than regular round brilliants. Only one

out of 300 pieces of rough is suitable for faceting this new cut and it

takes six times longer to produce than the round brilliant.

Xingguangda Diamond Jewelry Gallery

LORENZO JEWELRY INTERNATIONAL

Lorenzo Jewelry (LJ) International Inc. is the parent company to a

wholesale business, called Lorenzo, and a retail jewelry brand called

Enzo. The company is vertically integrated, with mining interests,

direct purchases from mines, colored gemstone manufacturing, jewelry

design and manufacturing, global wholesale distribution, and retail

sales. LJ International keeps its retail and wholesale businesses

separate by selling wholesale to markets globally and selling retail

through its stores in China.

The establishment of the Enzo retail division in

Mainland China completed LJ International’s full mine-to-market value

chain. Photo by Andrew Lucas/GIA, courtesy LJ International.

The company can trace its origins back to February, 1987, when the

current company Chairman, President, and CEO, Yu Chuan Yih, founded

Lorenzo Jewelry Manufacturing in Hong Kong. Mr. Yih was born in Brazil

and started in the industry as a Brazilian gemstone trader. The

company’s origin was very humble, with just five workers in the original

colored stone cutting factory.

Their first entry into China was in 1990, when they opened a 45,000 square foot colored gemstone cutting factory in Shantou, China. In 1998, they also opened a 50,000 square foot factory in Shenzhen. By 2003, they consolidated the operations into a 100,000 square foot highly modern Shenzhen facility. There, they cut colored gemstones, designed and manufactured jewelry, and conducted all their trading and corporate affairs.

Their first entry into China was in 1990, when they opened a 45,000 square foot colored gemstone cutting factory in Shantou, China. In 1998, they also opened a 50,000 square foot factory in Shenzhen. By 2003, they consolidated the operations into a 100,000 square foot highly modern Shenzhen facility. There, they cut colored gemstones, designed and manufactured jewelry, and conducted all their trading and corporate affairs.

Company founder Yu Chuan Yih has come a long way

from dealing colored stones in Brazil to leading this completely

vertically integrated company. Photo by Andrew Lucas/GIA, courtesy LJ

International.

Their major wholesale markets include the USA, Europe, and Japan, with

70 percent of their sales in the USA. They sell to many major companies,

including QVC, Ben Bridge, Sterling, Helzberg Diamonds, Macy’s,

Walmart, JC Penney, Signet, and Rhein Studios. Their lines include

sterling silver, various karat gold alloys, a variety of colored

gemstones, diamonds, and cultured pearls, as well as synthetic and

imitation gemstones.

At the Hong Kong Gem and Jewellery Fair, the

Lorenzo wholesale division sells loose colored stones and colored stone

jewelry to buyers from around the world. Photo by Andrew Lucas/GIA,

courtesy LJ International.

ENZO RETAIL DIVISION

The first Enzo retail store opened in Shanghai in December, 2004.

Today, Enzo has around 250 stores throughout Greater China, including

mainland China, Hong Kong, and Macau. Enzo has two divisions: the Enzo

chain of retail stores and Enzo Ouro, a new retail concept that serves

super VIP clients with high-end jewelry by appointment. The first Enzo

Ouro store opened in Beijing in 2014. Prices for Enzo Ouro jewelry range

from US$12,500 into the millions.

Enzo Ouro stores and showrooms exude luxury and exclusivity. Photo by Andrew Lucas/GIA, courtesy LJ International.

While known for loose colored gemstones and colored gemstone jewelry,

Enzo also has diamond lines that target the important wedding market in

China, which sees over 13 million marriages annually. Enzo breaks its

diamond line into three price-point ranges, with different diamond

qualities in each. Highest is Enzo 88, then Snowy, and then Cape. Enzo

88 has D to H color, Snowy has G to J color, and Cape has K through M

color. The Cape line has the largest market share of diamond jewelry for

Enzo.

LORENZO MANUFACTURING AND WHOLESALE

GIA visited LJ International’s corporate headquarters in Shenzhen to

observe their manufacturing process. Lorenzo cuts over 100 types of

colored gemstones in their facility. In the warehouse, rough is kept in

25-kilo bags, with more-expensive varieties like tourmaline stored in a

walk-in vault. Lorenzo primarily cuts colored gemstones other than ruby,

sapphire, and emerald, preferring to buy those stones already cut for

use in their finished jewelry.

Rubellite tourmaline is a big seller in China and an important stone for the Enzo retail

chain. Photo courtesy China Gems.

chain. Photo courtesy China Gems.

Lorenzo sources its rough from mines that the company has interests in,

from other mines, or from the open market. All rough goes first to

their office in Hong Kong and is housed in their massive warehouse.

Shenzhen is a free-trade zone, so having the factory there allows the

rough coming through Hong Kong to be declared to Chinese Customs with

stone type, weights, and values listed, then enter China through

Shenzhen and come directly to the Lorenzo factory with no taxes or

duties placed on it.

Lorenzo has an agreement with customs declaring the typical expected amount of weight loss after cutting. The new weights are listed for loose or jewelry-set finished stones, which are exported back to their Hong Kong office for global distribution.

Lorenzo has an agreement with customs declaring the typical expected amount of weight loss after cutting. The new weights are listed for loose or jewelry-set finished stones, which are exported back to their Hong Kong office for global distribution.

Copper-bearing tourmaline from Africa is one of

the gem varieties that Lorenzo brings into Shenzhen. They cut the stones

there for sale on the global market. Photo by Andrew Lucas/GIA,

courtesy LJ International.

This allows Lorenzo and other companies to smoothly import rough

gemstones into China, cut them, set them into jewelry, and export them

to the global market without paying import and export duties. Rough is

brought in by the gram and kilo while cut stones are exported by carat

weight and number of pieces. For gemstones destined for domestic retail

sale in Enzo stores, the company must pay duties that depend on stone

type and whether they’re rough or cut.

Lorenzo has more than 100 types of stones in their inventory room, broken down into three categories by value: Platinum, Gold, and Silver. The Silver level includes agates and other less-expensive aggregate materials; Gold contains facet-grade material like amethyst, citrine, garnet, and blue topaz; and Platinum contains more-expensive facet-grade material like tourmaline (including copper-bearing), imperial topaz, pink topaz, kunzite, and morganite.

Lorenzo has more than 100 types of stones in their inventory room, broken down into three categories by value: Platinum, Gold, and Silver. The Silver level includes agates and other less-expensive aggregate materials; Gold contains facet-grade material like amethyst, citrine, garnet, and blue topaz; and Platinum contains more-expensive facet-grade material like tourmaline (including copper-bearing), imperial topaz, pink topaz, kunzite, and morganite.

Rough is sorted by color, shape, clarity, and

size. Lorenzo uses color master sets as references, so customers can

order material that is reliably consistent. Photo by Andrew Lucas/GIA,

courtesy LJ International.

Their sorting department uses rough masterstones to grade color. They

have six color classifications for each type of gemstone. For example,

the six color grades for citrine range from CS (citrine super

excellent), CE (citrine excellent), and then C1, C2, C3, and C4. The

rough’s final grade is based on color, shape, thickness, and clarity. At

this point and after each manufacturing stage—sawing, preform, and

faceting—the rough is also given a weight yield projection. If the

weights after each stage are less than the projection, they review that

manufacturing stage.

The sawing, also called slicing, stations are set up so the sawing wheel is enclosed, with a viewing screen and an opening for the worker’s hands. This set-up, along with a face mask, vacuum tubes drawing gemstone dust away, and water applied to the rough, minimizes the worker’s exposure to the dust resulting from the sawing process.

The sawing, also called slicing, stations are set up so the sawing wheel is enclosed, with a viewing screen and an opening for the worker’s hands. This set-up, along with a face mask, vacuum tubes drawing gemstone dust away, and water applied to the rough, minimizes the worker’s exposure to the dust resulting from the sawing process.

Most of Lorenzo’s workers who do the sawing and

preforming have over 10 years of experience. Photo by Andrew Lucas/GIA,

courtesy LJ International.

After sawing, the preform stage uses a grinding wheel to shape the

stone. The preform set-up is also designed to minimize workers’ exposure

to gemstone dust. Workers wear masks, and a vacuum tube draws dust away

at each grinding station.

The set-up at the faceting stations uses two lapidaries: one for cutting and the other for polishing. While this system is not unique, the custom-built lapidary machines from Korea were set up in an arrangement designed for left-handed workers. The reason for this is the competitive nature of hiring skilled cutters in Shenzhen. Cutters are often hired away from one manufacturer to another. However, almost all two-lap cutting systems are designed for right-handed workers. By having left-handed machines, Lorenzo minimizes the hiring away of its cutters.

Lorenzo cuts all their copper-bearing tourmaline in a separate section that encompasses all stages: rough sorting, sawing, preforming, and faceting. This confinement to one area makes it possible to secure the expensive material.

The set-up at the faceting stations uses two lapidaries: one for cutting and the other for polishing. While this system is not unique, the custom-built lapidary machines from Korea were set up in an arrangement designed for left-handed workers. The reason for this is the competitive nature of hiring skilled cutters in Shenzhen. Cutters are often hired away from one manufacturer to another. However, almost all two-lap cutting systems are designed for right-handed workers. By having left-handed machines, Lorenzo minimizes the hiring away of its cutters.

Lorenzo cuts all their copper-bearing tourmaline in a separate section that encompasses all stages: rough sorting, sawing, preforming, and faceting. This confinement to one area makes it possible to secure the expensive material.

Lorenzo uses a two-lap faceting system. The lap

on the left is for cutting and the one on the right is for polishing.

Photo by Andrew Lucas/GIA, courtesy LJ International.

THE FINISHED PRODUCT

Lorenzo’s operation covers the entire value chain, from buying and

cutting rough colored gemstones to mounting them in jewelry. They also

have a wholesale export business and domestic retail stores.

Our tour through LJ International’s multi-story Shenzhen headquarters

took us into their jewelry design and manufacturing facilities. Their

designs start out as hand renderings that are scanned and cleaned up

with Microsoft Paint before moving on to the CAD/CAM division. The

digital design file is sent to a Fast Prototyping Machine that creates

the first wax model through a laser printing process that takes six

hours. The wax form is then cast in silver to make a master model.

Lorenzo reports that they have approximately 120,000 metal master models

on hand.

The entire production facility was well

organized, modern, and clean, and emphasized worker safety and health.

Photo by Andrew Lucas/GIA, courtesy LJ International.

At the jewelry-design stage, the model-production

process starts with converting a hand drawing into a computer file. The

file is then sent to a machine that creates a prototype. Photo by

Andrew Lucas/GIA, LJ International.

This worker is attaching wax forms to a tree so

several pieces can be cast at the same time. Photo by Andrew Lucas/GIA,

courtesy LJ International.

Intricate stone setting is performed with the assistance of a microscope. Photo by Andrew Lucas/GIA, courtesy LJ International.

Lorenzo’s mass-production areas start with stone sorting, quality

control, and stone matching for jewelry. Their diamond melee sorters

move at an amazing speed, louping a stone about every second. Colored

stones are matched to master sets so customers can confidently order

additional material in the future and know they will receive the same

consistent qualities.

Cut stones are graded against a master set,

quality-inspected, and matched for jewelry. Photo by Andrew Lucas/GIA,

courtesy LJ International.

The production process involves selecting the mold needed from the

company’s rubber mold library and then moving through wax injection,

removing the wax from the rubber mold, preparing the wax for casting,

casting the piece, preparing the jewelry for stone setting, setting the

stones, final polish, and final quality control. Some casting is done

with stones like diamond, sapphire, and ruby already set in the wax.

Diamonds will be placed in this wax model to be

cast in place, eliminating the need for a gem-setting step. Photo by

Andrew Lucas/GIA, courtesy LJ International.

Step inside Lorenzo’s massive gem vault and learn the intricacies of

import and export for gem materials in China as well as How Lorenzo

clasifies and stores their gem material.

CONCLUSION

Our visit to Shenzhen, with stops at the Shuibei International Jewelry

Trade Center, The Royalland Jewelry Club, Batar Jewelry, Xingguangda

Jewelry, and LJ International, provided us with an important overview of

that modern, bustling city’s dynamic jewelry industry. Because of the

vertically integrated nature of its businesses, we also gained important

information about the general structure of the Chinese gem and jewelry

industry.

No comments:

Post a Comment